Imagine flipping a switch and nothing happens. Frustrating, right? In the world of electrical work, precision isn’t just a nice-to-have; it’s a necessity. When you’re dealing with wiring, circuits, and voltage, even the smallest error can lead to costly mistakes or dangerous outcomes.

In this article, I’ll dive into why getting it right the first time is crucial for anyone in the electrical field. You’ll discover how precision impacts safety, efficiency, and the overall quality of your work. If you’ve ever worried about the repercussions of a miscalculation, this discussion will provide the insights you need to elevate your skills and ensure your projects are successful. Let’s explore how attention to detail can make all the difference.

Understanding Precision in Electrical Work

Precision in electrical work refers to the exactness and care required in every aspect of the job. It directly affects the safety and effectiveness of electrical systems. Professionals in this field must grasp the following concepts to ensure successful project outcomes.

Definition of Precision

Precision denotes the degree of refinement in measurements and execution within electrical tasks. It involves not just adhering to numerical values but applying them consistently across all components. When measurements such as voltage, current, or resistance are exact, it minimizes the risk of failures. An example includes using the right gauge wire for specific electrical loads, avoiding overheating and potential fires.

Importance of Accuracy

Accuracy stands at the core of effective electrical work. High accuracy ensures that systems operate as designed, reducing the likelihood of failures or hazards. It drives the following critical points:

Safety: Precise work prevents accidents, reducing risks of shocks or fire hazards. When installations are accurate, it protects both workers and end-users.

Efficiency: Accurate measurements contribute to optimal performance. Energy efficiency improves when systems function correctly, saving costs and resources over time.

Quality: Projects completed with high accuracy reflect skill and professionalism. This builds trust with clients and enhances reputation.

Incorporating accuracy into every facet of work fosters a culture of reliability. Understanding precision not only enhances individual capabilities but also contributes to the overall integrity of the electrical profession.

The Role of Precision in Safety

Precision plays a crucial role in ensuring safety within electrical work. Even small mistakes can trigger safety hazards that jeopardize lives, property, and projects. Therefore, maintaining a high level of accuracy is essential in every step of the process.

Reducing the Risk of Electrical Hazards

Precision reduces the risk of electrical hazards by ensuring that installations and repairs are done correctly. Accurate measurements and careful calculations prevent issues like short circuits, overloads, and electrical shocks.

Properly sized wires reduce fire risks, ensuring circuits can handle the expected load without overheating.

Actively following precision practices promotes safety and boosts confidence in the electrical work being performed. Accurate work decreases the likelihood of failures that can lead to dangerous situations.

Ensuring Compliance with Codes and Standards

Compliance with electrical codes and standards hinges on precision. Each code outlines specific guidelines for design, installation, and maintenance to protect users and property.

Meeting National Electrical Code (NEC) requirements prevents legal repercussions and enhances safety.

Following precise methods ensures adherence to these guidelines. Professionals who prioritize accuracy not only safeguard others but also uphold the integrity of their work. Complying with standards fosters trust in both clients and the broader community.

By centralizing precision in every task, I can ensure greater safety outcomes and reassure all stakeholders involved.

Impact of Precision on Performance

Precision plays a fundamental role in the performance of electrical systems. Accurate measurements and thoughtful execution lead to safe, efficient, and reliable operations. Understanding its impact in electrical work can enhance various aspects of performance.

Improving System Efficiency

Maintaining system efficiency heavily relies on precision. When electrical components are aligned and connected correctly, energy loss decreases significantly. Minor inaccuracies can cause mismatches between components, leading to inefficiencies.

Optimized performance: Precise connections facilitate optimal current flow, reducing resistance and heat generation. This aligns all components to function at their best, which ultimately saves energy and extends the lifespan of equipment.

By focusing on precision, I ensure that installations perform efficiently and that energy resources are used wisely, which is crucial in an age of rising energy costs.

Enhancing Reliability and Longevity

Precision greatly enhances the reliability and longevity of electrical systems. Accurate measurements prevent components from being subjected to undue stress or failure.

Minimized wear and tear: Properly fitted components experience less strain, leading to fewer breakdowns and maintenance needs. Over time, this precision translates to equipment that operates reliably over long periods.

When I prioritize precision, I'm not just ensuring current functionality; I'm also investing in long-term performance. Reliable systems reduce downtime and save costs associated with repairs or replacements, maintaining a smoother workflow in my projects.

Tools and Techniques for Achieving Precision

Precision in electrical work hinges on the right tools and techniques. Using high-quality equipment helps ensure accuracy and safety in every task.

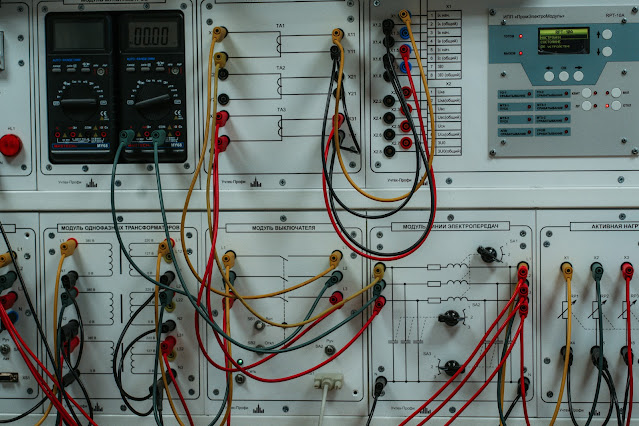

Essential Tools for Electricians

Tools play a vital role in maintaining precision during electrical work. Some essential tools include:

Digital Multimeter: This tool measures voltage, current, and resistance, allowing for accurate diagnostics and confirming proper function.

Wire Strippers: Strippers provide precision cuts to ensure clean ends, which help maintain strong connections.

Fish Tape: Used for running wire through walls, it helps in maintaining smooth pulls and reducing damage to surrounding materials.

Level: Ensures that installations are straight, preventing future issues related to alignment.

Torque Wrench: This tool allows for applying correct tension on connections, promoting safety and effectiveness.

Choosing the right tools enhances accuracy and minimizes the likelihood of errors, which can lead to costly mistakes.

Best Practices in Electrical Installations

Adopting best practices significantly impacts the precision of electrical work. Key practices include:

Follow Schematics Closely: Always reference schematics to guide wiring and component placement. This helps avoid incorrect connections.

Measure Twice, Cut Once: This well-known principle reinforces careful measuring to reduce mistakes and waste.

Label All Wires: Clearly labeling wires simplifies the installation or repair process, reducing confusion and potential errors.

Use Quality Materials: Investing in high-quality materials ensures reliable performance and reduces the risk of malfunction.

Double-Check Connections: A routine verification process for all connections reduces the chance of faults down the line.

By following these best practices, electrical professionals can enhance their work’s accuracy and reliability, ensuring successful project outcomes.

Conclusion

Precision in electrical work isn’t just a luxury; it’s a necessity. I’ve seen firsthand how meticulous attention to detail can transform a project from mediocre to outstanding. When I prioritize accuracy in my work, I don’t just enhance safety and efficiency; I also build trust with my clients and the community.

By committing to precision, I contribute to the integrity of the electrical profession. Each careful measurement and thoughtful execution not only safeguards lives but also ensures that systems perform optimally. As I continue to refine my skills and adopt best practices, I realize that precision is the key to long-term success in this field. Embracing this mindset will lead to better outcomes and a more reliable future in electrical work.

Frequently Asked Questions

What is the importance of precision in electrical work?

Precision in electrical work is crucial because even minor errors can lead to significant safety hazards and operational issues. It ensures that installations are safe, efficient, and reliable. Achieving precision minimizes risks of accidents, enhances performance, and reflects professionalism in the electrical field.

How does precision affect safety in electrical projects?

Precision directly impacts safety by preventing incorrect installations and repairs that could lead to short circuits, overloads, or worse. Accurate work reduces the chances of electrical hazards, ensuring that all systems operate as designed and that stakeholders' lives and properties are protected.

What tools are essential for achieving precision in electrical work?

Essential tools for achieving precision include digital multimeters, wire strippers, fish tape, levels, and torque wrenches. These tools help electricians ensure accuracy and safety, facilitating the careful execution of tasks and adherence to industry standards.

What best practices should electricians follow to ensure precision?

Electricians should follow best practices such as measuring twice before cutting, closely adhering to schematics, labeling wires, using quality materials, and double-checking connections. These habits help improve the accuracy and reliability of their work, leading to better outcomes.

How can precision impact the efficiency of electrical systems?

Precision enhances the efficiency of electrical systems by ensuring optimal component matching and decreasing energy loss. Accurate measurements facilitate proper current flow, which can reduce resistance and heat generation, ultimately saving energy and increasing the lifespan of equipment.